Other tests on rubber compounds

Wide variety of advanced equipment

With a wide variety of advanced equipment in the laboratory, ERT can test or measure the following properties of rubber:

The tests are carried out as standard in accordance with ASTM, DIN and/or ISO standards. We can also meet any customer-specific test requirements.

Would you like more information about tests on rubber compounds?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

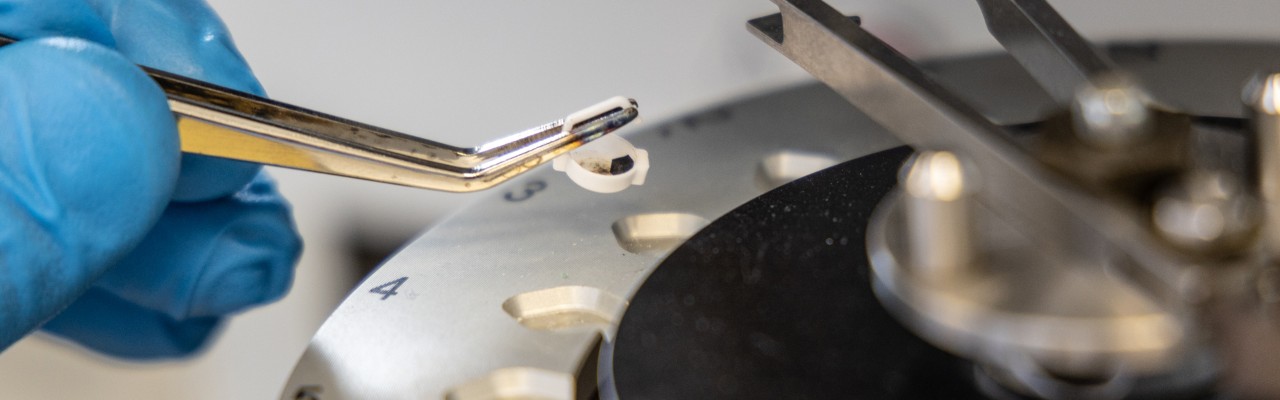

Steel-cord adhesion of rubber compounds

(ISO5603)

Some demanding rubber products are reinforced with steel-cord. In such products the performance is dependent on the adhesion between steel and rubber. To determine the adhesion of vulcanized rubber to steel cord, specific test pieces are prepared at ERT and tested according to ISO-5603. It is also possible to examine the impact of various conditions of ageing on adhesion, for example hot-air, steam and salt ageing.

The test is carried out according to ISO standard 5603, unless otherwise desired.

Interested in steel-cord adhesion?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Adhesion to rigid materials

(e.g. metal, plastic) ISO813

Rubber products often involve rubber fixed to rigid materials, such as steel or plastic. With well-defined test samples, the adhesive strength can be measured. Upon failure, the test samples show adhesive (breaking the interface) and/or cohesive failure (rubber tear). For product design purposes, a cohesive failure mechanism is often preferred.

The test is carried out according to ISO standard 813, unless otherwise desired.

Would you like more information about adhesion to rigid materials?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

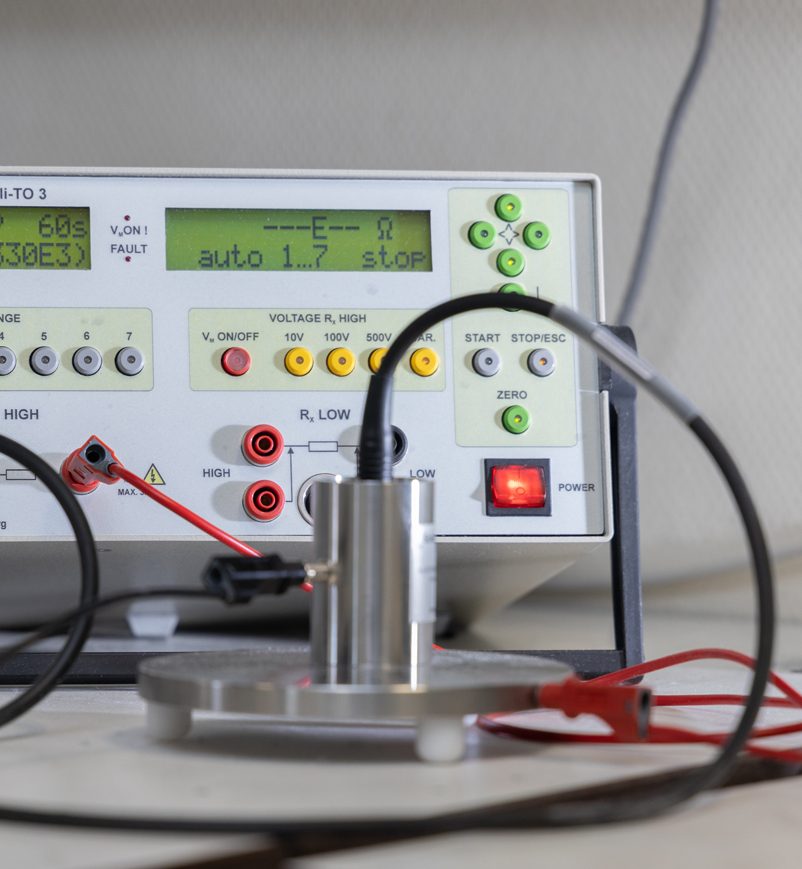

Electrical conductivity through rubber products

Generally, rubber is an electrical insulator although low conductivity can be improved by addition of specific additives. The degree of conductivity, both surface and volume, can be determined in the lab.

Would you like to know more about electrical conductivity?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

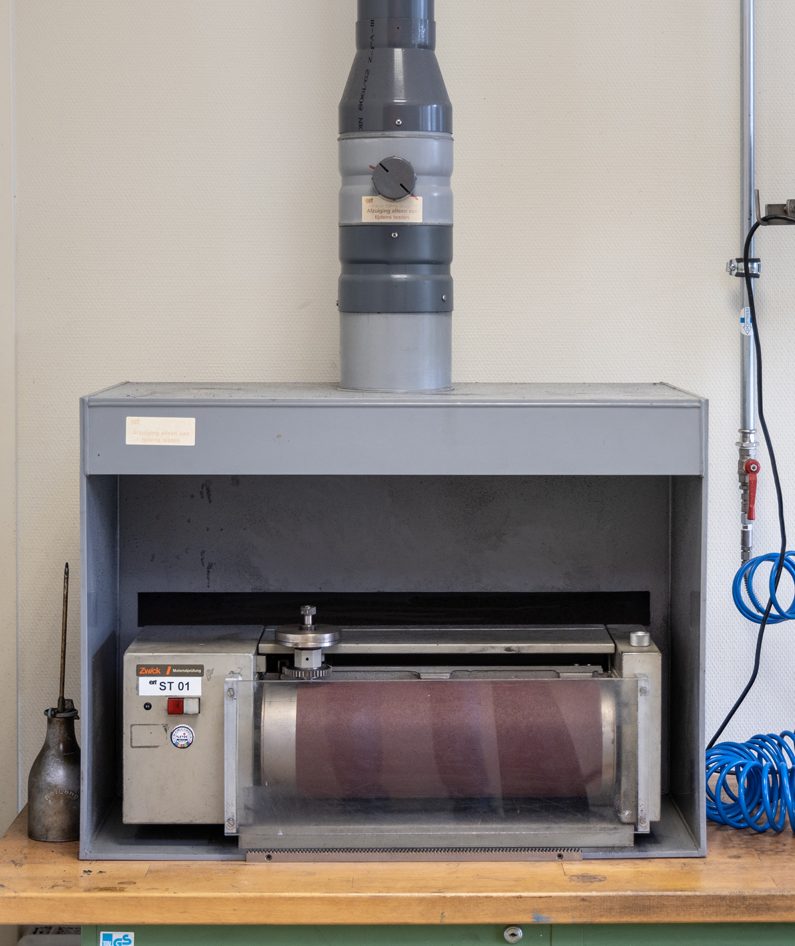

Friction resistance of rubber materials

(ISO15113)

When dry, rubber has a very high friction resistance compared to other materials. But when it is wet, friction resistance disappears almost completely.

Indications of these friction resistances can be found by determining the force needed to move a particular material across the rubber surface.

The test is carried out according to ISO standard 15113, unless otherwise desired.

Would you like more information about friction resistance?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Thermal expansion coefficient of rubber compounds

Most materials, including rubber, expand upon heating. Accounting for this property is essential when designing and simulating production tools, rubber products, and functional performance. The degree of thermal expansion can be measured over a specific temperature range.

Would you like more information about the thermal expansion coefficient?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Flammability tests (e.g. LOI, UL 94) of rubber compounds ISO4589-2

Some rubber materials are inherently more fire resistant than others. For many compounds, adding flame retardants can increase fire resistance. Fire resistance can be determined in a number of ways (including LOI and UL 94).

The test is carried out according to ISO standard 4589-2 and other standards, unless otherwise desired.

Interested in flammability?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

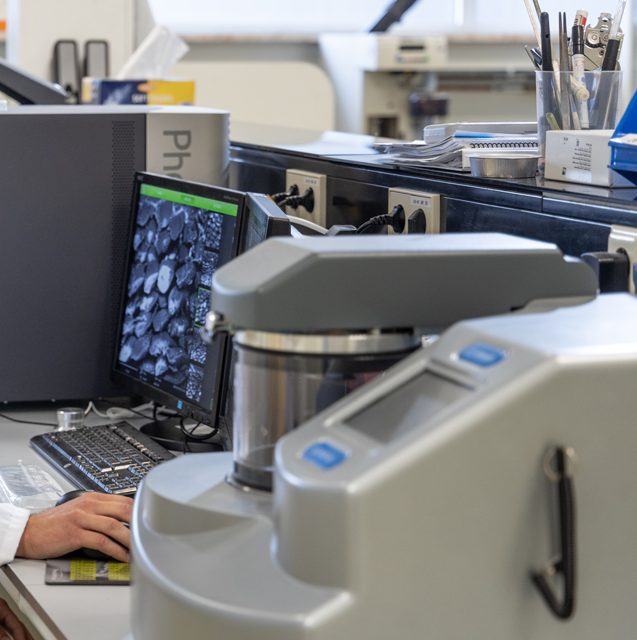

Powder characterisation (e.g. particle size distribution and BET and/or CTAB surface area)

The powder characteristics of, for example, carbon black and/or mineral fillers give an indication of the reinforcing properties and therefore of the ultimate mechanical properties of the rubber material.

This reinforcing effect depends partly on particle size, surface area and distribution.

Would you like more information about powder characterisation?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Information request about other tests

Privacy

Your information will not be used for any other purpose and will not be provided to third parties. Your data can be deleted at any time. For more information about how we process your data, please see our privacy statement.

We will be happy to help you

Location

Elastomer Research Testing BV

Teugseweg 27

7418 AM Deventer the Netherlands

Postal address

Elastomer Research Testing BV

PO Box 2149

7420 AC Deventer the Netherlands

Contact

E info@ertbv.com

T +31 570 62 46 16

F +31 570 62 57 02