Environmental and ageing impact on rubber compounds

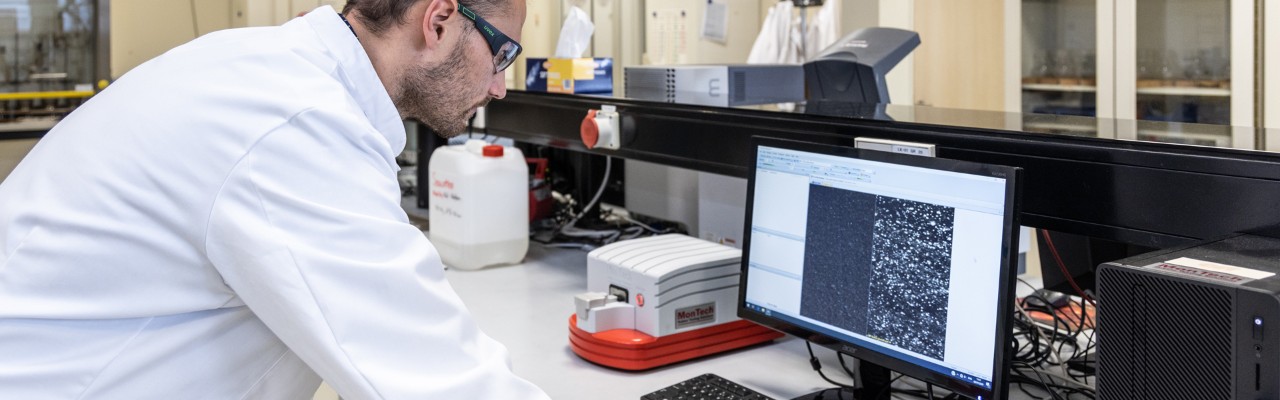

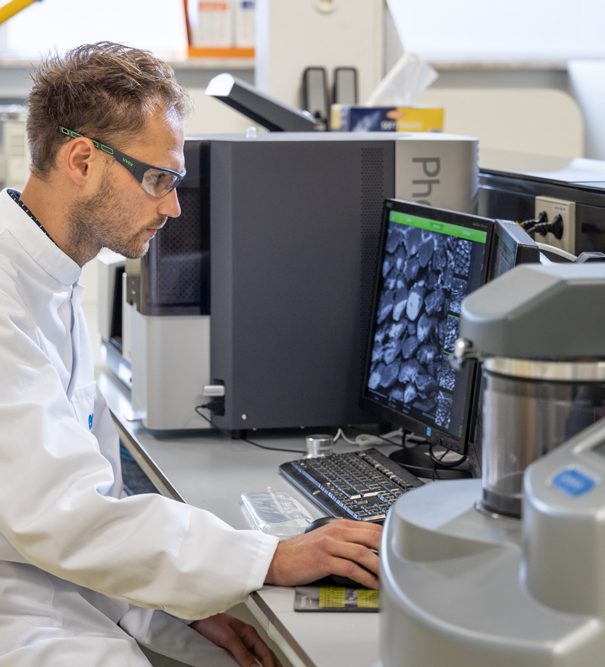

Wide variety of advanced equipment

With a wide variety of advanced equipment in the laboratory, ERT can test or measure the following properties of rubber:

The tests are carried out as standard in accordance with ASTM, DIN and/or ISO standards. We can also meet any customer-specific test requirements.

Would you like more information about tests on rubber compounds?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Hot-air ageing of rubber products (ISO188)

All rubber products are subject to ageing, and this process is accelerated with increasing temperature. Hot-air ageing provides time dependent insight into the temperature resistance based on changes in for example hardness, tensile strength, elongation at break, stiffness, mass and volume.

Ageing tests at different elevated temperatures also allow to extrapolate the expected service life.

The test is carried out according to ISO standard 188, unless otherwise desired.

Do you have a question about hot-air ageing?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Ozone resistance (static and dynamic) of rubber products

Rubber products used in the open air may be affected by ozone O3 (which is present in the atmosphere). Exposure to ozone may result in crack formation, and eventually cause complete product failure. Some rubber compounds are ozone resistant while others can be mixed with anti-degradants that make them ozone resistant during a specific service life. Ozone resistance can be tested at different temperatures, ozone concentrations and exposure times. Standard test conditions are 50pphm ozone, 40°C and 20% elongation.

The test is carried out according to ISO standard 1431-1, unless otherwise desired.

Would you like more information about ozone resistance?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Resistance of rubber to light and weather conditions, and colour change measurement (ISO4892-2)

Rubber product that are exposed to sunlight may show changes in materials properties. Sunlight often causes discoloration while the UV portion of the radiation can cause polymer degradation. At ERT a Xenon tester is operated which has a radiation spectrum closer to sunlight compared to a QUV test chamber. The difference between a QUV and a sunlight tester (Xenon) is that a QUV tester only irradiates UV-A, B and C, while a Xenon tester only tests with some UV-A, visible light and infrared light (IR).

Rubber products used outdoors are humid about 50% of the time due to rain, humidity, dew etc. That is why the Xenon tester also has the option of testing several cycles of demi-water spraying.

After ageing for a specified period, the difference in colour is measured and expressed as l, a, b-values, resulting in ΔE, which is an indication of the total discolouration. Furthermore, changes in material properties can be determined.

The test is carried out according to ISO standard 4892-2, unless otherwise desired.

Interested in weather influences on rubber?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Steam ageing in rubber products

Rubber materials generally perform differently in steam (water vapor) than compared to hot air (oxygen containing environment). The steam autoclave can heat water up to 125°C for a specific period, after which the change in material properties is measured including hardness, tensile strength, elongation at break, stiffness, and if requested steel-cord adhesion. The steam autoclave can also be used as a sterilizer.

The test is carried out using an in-house test method, unless otherwise desired.

Would you like more information about the steam ageing of rubber?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Effect of fluids and/or chemicals on rubber compounds (ISO1817)

The resistance of rubber compounds to certain fluids and/or chemicals is expressed in the change in tensile strength, elongation at break, hardness, volume and mass after immersion in the fluids and/or chemicals to be tested for a specified time at a specified temperature.

The test is carried out according to ISO standard 1817, unless otherwise desired.

Are you interested in the effect of chemicals on rubber?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Contact and migration discolouration (ISO3865)

Measuring the degree of staining of materials in contact with or near rubber. This can be caused by ingredients of the rubber compound migrating to the surrounding material.

The test is carried out according to ISO standard 3865, unless otherwise desired.

Do you have a question about the contact discolouration of rubber?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Service life-time expectancy of rubber compounds (ISO11346)

The Arrhenius method can be used to obtain an indication of the life expectancy of the rubber materials and/or products. This is done by means of accelerated ageing analyses, measuring at different elevated temperatures how long it takes for the decrease of certain material properties to reach a certain point. Using the Arrhenius extrapolation, this then yields a prognosis of how long it will take for this material property to be reached at the operating temperature.

The test is carried out according to ISO standard 11346, unless otherwise desired.

Would you like more information about service life-time expectancy?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Information request about environmental and/or ageing tests

Privacy

Your information will not be used for any other purpose and will not be provided to third parties. Your data can be deleted at any time. For more information about how we process your data, please see our privacy statement.

We will be happy to help you

Location

Elastomer Research Testing BV

Teugseweg 27

7418 AM Deventer the Netherlands

Postal address

Elastomer Research Testing BV

PO Box 2149

7420 AC Deventer the Netherlands

Contact

E info@ertbv.com

T +31 570 62 46 16

F +31 570 62 57 02