Dynamic properties

Wide variety of advanced equipment

With a wide variety of advanced equipment in the laboratory, ERT can test or measure the following properties of rubber:

The tests are carried out as standard in accordance with ASTM, DIN and/or ISO standards. We can also meet any customer-specific test requirements.

Would you like more information about tests on rubber compounds?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

DeMattia flex tests on rubber compounds (ISO132)

Continuous flexing or movement in a rubber product may cause cracks to form in the area where forces build up beyond the material limits. Once a crack has initiated, it will keep propagating, eventually causing the product to fail. This test distinguishes between two methods:

- flex cracking: the number of movements it takes before a crack initiates

- crack growth: after introducing a well-defined crack, the crack growth is measured upon continuous flexing

It is essentially a fatigue test under flexing.

The test is carried out according to ISO standard 132, unless otherwise desired.

Do you have a question about the DeMattia flex test?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Fatigue-to-failure test (ISO6943)

The effect of repeated rubber stretching can be determined with a fatigue-to-faulure test. With the test it is possible to determine rubber fatigue when exposed to repeated cyclical stretching deformations. This test can be performed in two different ways:

- how often can a test piece be cyclically stretched at a certain rate before it breaks

- what is the permanent deformation after a set number of cyclical elongations

This is a stretch fatigue test.

The test is carried out according to ISO standard 6943, unless otherwise desired.

Would you like more information about fatigue-to-failure?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Goodrich Flexometer (HBU and blow-out) ISO4666-3

Cyclic compression of rubber causes heat to develop in the material, which may eventually result in complete internal degradation of the rubber. This test, which is normally performed at 30Hz, a 1MPa static load followed by a dynamic stroke of 4.45mm, measures the temperature rise, creep and permanent deformation of a rubber material under dynamic load during and after the test. This is called the Heat Build-Up (HBU) test. If the static load is raised to 2MPa, the test is known as a blow-out test (BO).

The test is carried out according to ISO standard 4666-3, unless otherwise desired.

Interested in Goodrich Flexometer?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

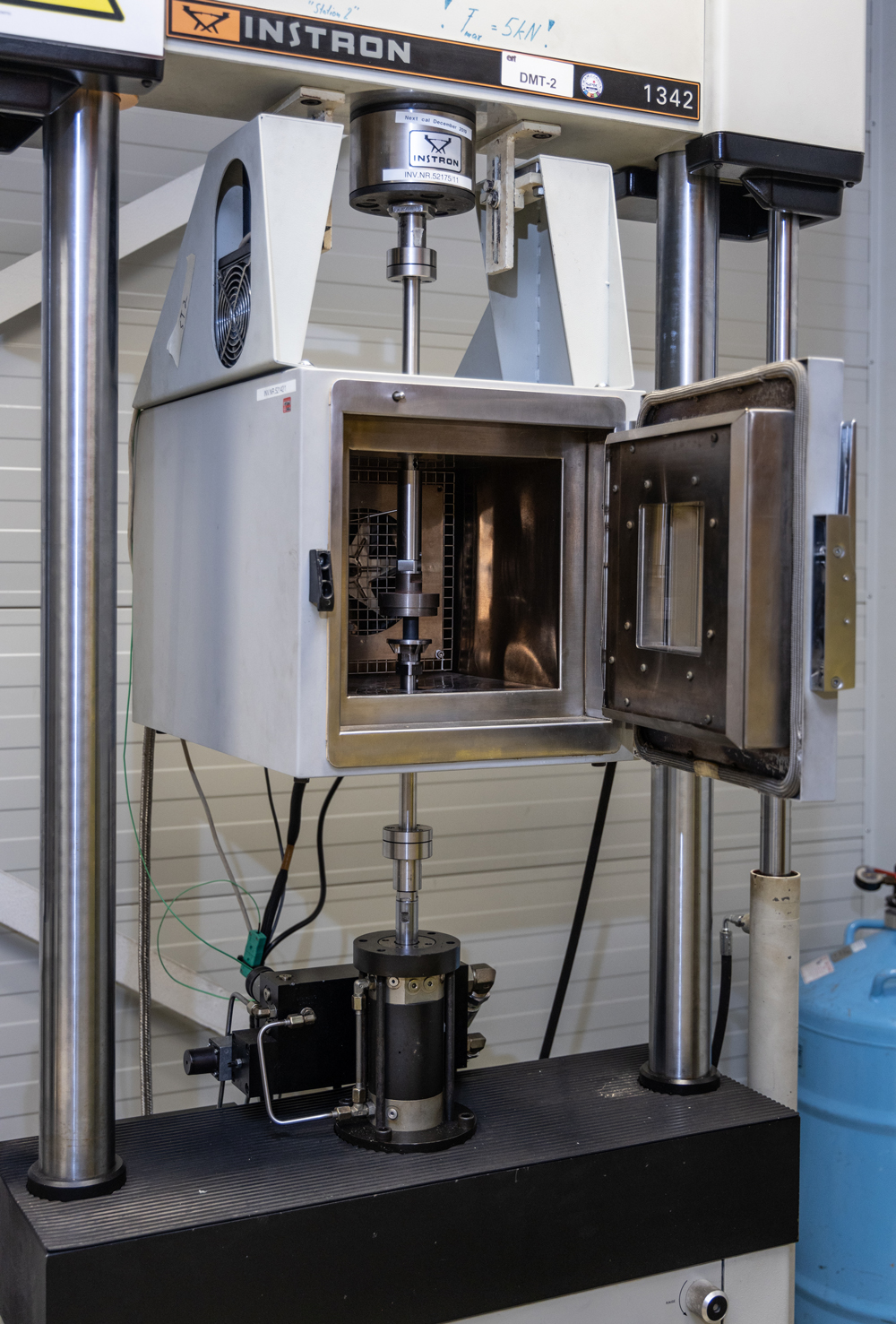

Dynamic-Mechanical-Thermal Analysis (DMTA) ISO4664-1

DMTA (Dynamic Mechanical Thermal Analysis) is used to determine the temperature and frequency dependent visco-elastic properties of vulcanized rubber under various elongation, compression or shearing rates. The machine measures, amongst other things, the storage and loss moduli and the resulting tan δ: ratio to loss and storage modulus.

DMTA can be used to measure:

- Low temperature properties: a dynamic test over a specified temperature range yields a tan δ curve; the peak in this curve is an indication of the glass transition temperature of the material under the applied test conditions. That makes it easier to estimate whether the material will still be rubbery at certain temperatures and conditions and so, for instance, still retain its sealing properties.

The test is carried out according to ISO standard 4664-1, unless otherwise desired.

Would you like more information about Dynamic Mechanical Thermal Analysis (DMTA)?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Chip-and-chunk resistance of rubber compounds

This method can measure the resistance of vulcanised rubber to rubber chips breaking off under cyclic load of falling blunt material.

The test is carried out according to the ERT 612 in-house test method, unless otherwise desired.

Would you like more information about chip-and-chunk resistance?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Information request about dynamic properties tests

Privacy

Your information will not be used for any other purpose and will not be provided to third parties. Your data can be deleted at any time. For more information about how we process your data, please see our privacy statement.

We will be happy to help you

Location

Elastomer Research Testing BV

Teugseweg 27

7418 AM Deventer the Netherlands

Postal address

Elastomer Research Testing BV

PO Box 2149

7420 AC Deventer the Netherlands

Contact

E info@ertbv.com

T +31 570 62 46 16

F +31 570 62 57 02