Chemical analysis of rubber compounds

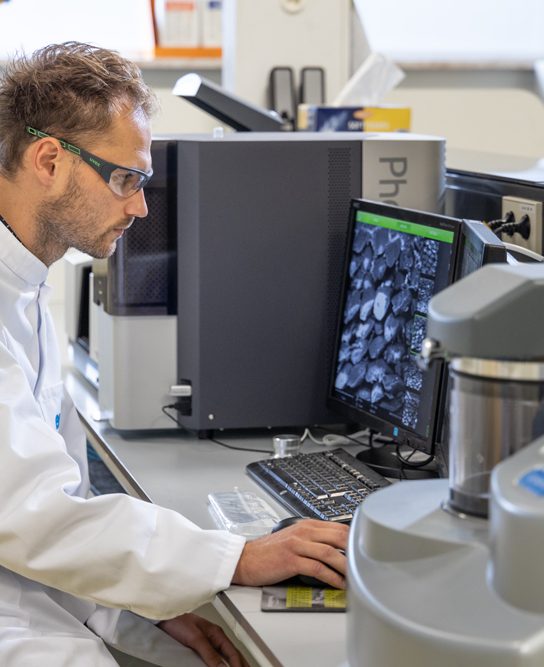

Wide variety of advanced equipment

With a wide variety of advanced equipment at ERT, we can precisely analyze the following properties of rubber:

The tests are generally carried according to ASTM, DIN and/or ISO standards. Nevertheless the expertise at ERT especially allows to adjust to your specific test requirements.

Would you like more information about tests on rubber compounds?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Soxhlet extraction (e.g. drinking water and food industry) of rubber materials (ISO1407)

To comply to food and/or water legislation (e.g. EC1935, FDA) it’s often required to measure the extractable matter of rubber materials. This can be determined using Soxhlet extraction in predetermined solvents or solids. This is important for industries like the drinking water and food industries, where a maximum allowable extractable matter applies.

The test is carried out according to ISO standard 1407, unless otherwise desired.

Interested in Soxhlet extraction?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Determination of polymer type in rubber compounds

FTIR spectroscopy is a powerful method to rapidly determine the type of polymer. FTIR analysis of a rubber material yields a spectrum, fingerprint, in which every peak represents a particular chemical compound. This spectrum can be used to determine what polymer a material is. This method is also very effective as a fingerprint to demonstrate the consistency of materials, because it shows very quickly whether spectra change over time.

Would you like to know more about polymer type determination?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Reverse engineering (e.g. FTIR, TGA, NMR, pyrolyse-GCMS, HPLC, SEM-EDX)

Reverse engineering, using all kinds of analytical techniques, provides, as accurately as possible, insight into the entire chemical composition of a material.

TGA analysis is used to reveal the content of polymer, the amount of carbon black, volatile matter and ash (mineral fillers). With reverse engineering it is also possible to reveal the type of plasticizers and mineral fillers, as well as other additives like antioxidants, resins and which vulcanization ingredients.

Therefore, reverse engineering can be highly informative for competition analysis.

Would you like to know more about reverse engineering?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

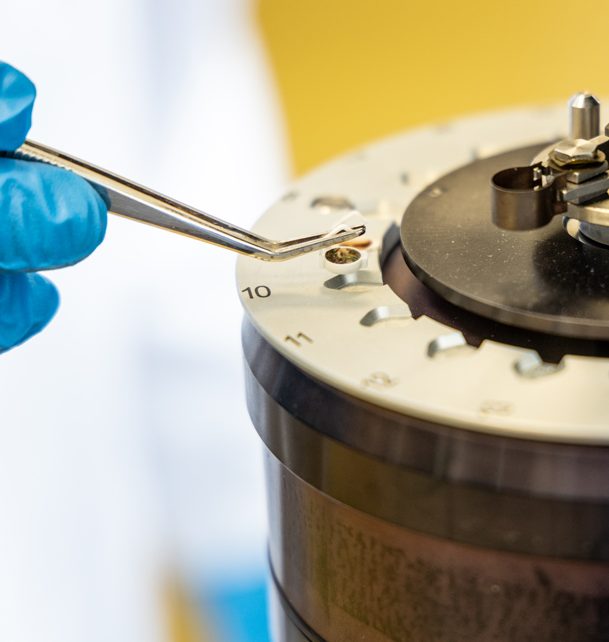

TGA (determination of amount of Polymer, volatile components, carbon black and mineral fillers)

ISO9924-1 to 3

TGA (Thermal Gravimetric Analysis) reveals the content of polymer, carbon black, volatile matter and ash (mineral fillers) by means of burning at certain temperatures in the presence of oxygen or nitrogen. This method is also effective as a fingerprint to demonstrate the consistency of the compound composition.

The test is carried out according to ISO standard 9924-1 to 3, unless otherwise desired.

Do you have a question about Thermal Gravimetric Analysis?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

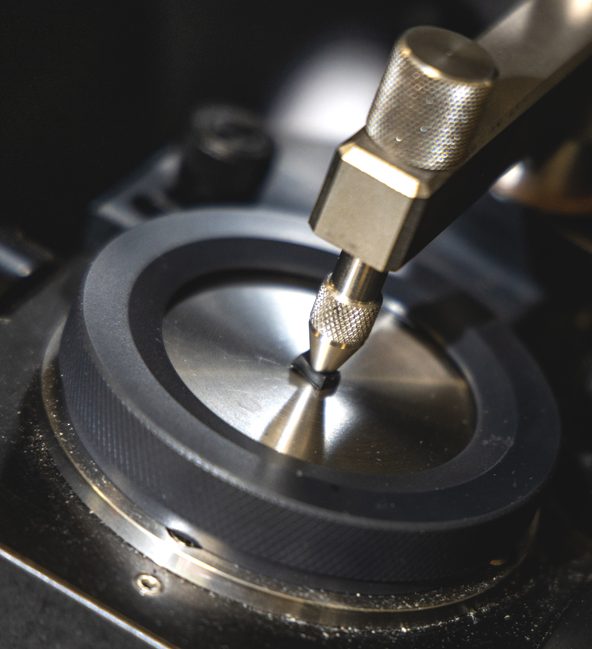

Cross-link density and distribution

To determine the crosslink density ERT provides a combination of swelling tests and chemical probe reactions, as well as its mono, di, and polysulphidic distribution in case of a sulfur-cured rubber product.

The test is carried out according to the in-house ERT 613 test method, unless otherwise desired.

Would you like more information about cross-link density?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Information request about chemical analysis

Privacy

Your information will not be used for any other purpose and will not be provided to third parties. Your data can be deleted at any time. For more information about how we process your data, please see our privacy statement.

We will be happy to help you

Location

Elastomer Research Testing BV

Teugseweg 27

7418 AM Deventer the Netherlands

Postal address

Elastomer Research Testing BV

PO Box 2149

7420 AC Deventer the Netherlands

Contact

E info@ertbv.com

T +31 570 62 46 16

F +31 570 62 57 02