Compound development

ERT is passionate and specialized in rubber compound development.

Our expertise and decades of experience are used to design, mix, test and optimize a recipe to achieve the desired material properties. The resulting intellectual property (recipes) and corresponding test results are shared with our customers. A basis for compound development can be:

Co-engineering

ERT develops a compound based on the client's set of requirements (e.g. application, processing, material specification, occupational and environmental aspects and price). A trial-and-error approach is also possible, for example if a customer needs a new rubber material, but does not exactly know what its required properties should be. In this case, a compound is worked on until the desired effect is achieved.

Reverse engineering

Based on in-depth chemical analysis of an existing product at ERT, a recipe will be developed that has equivalent or preferably improved materials properties. There are different compound mixing lines for black and colored compounds.

The tests are carried out as standard in accordance with ASTM, DIN and/or ISO standards. We can also meet any customer-specific test requirements.

Do you have a question about compound development?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

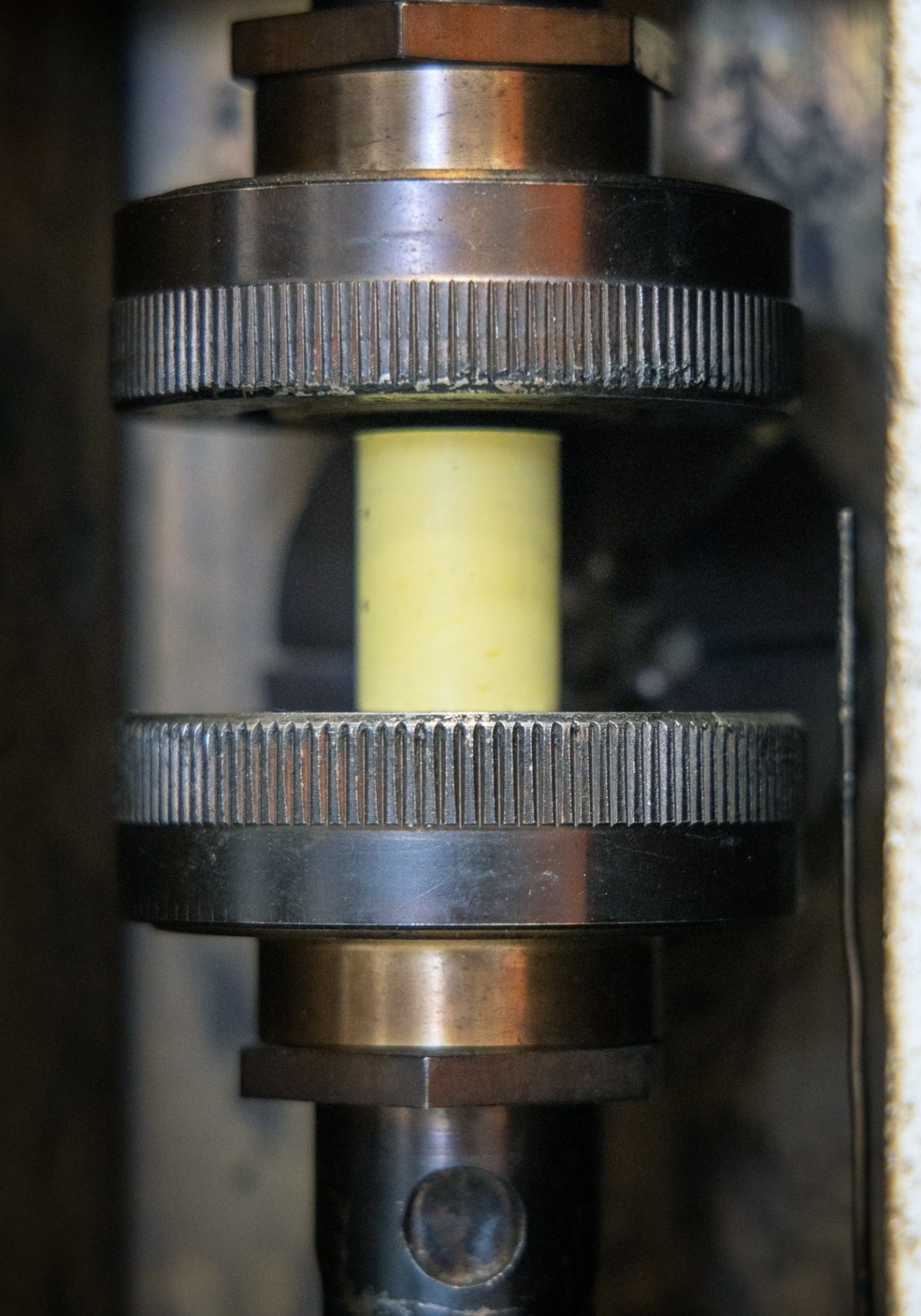

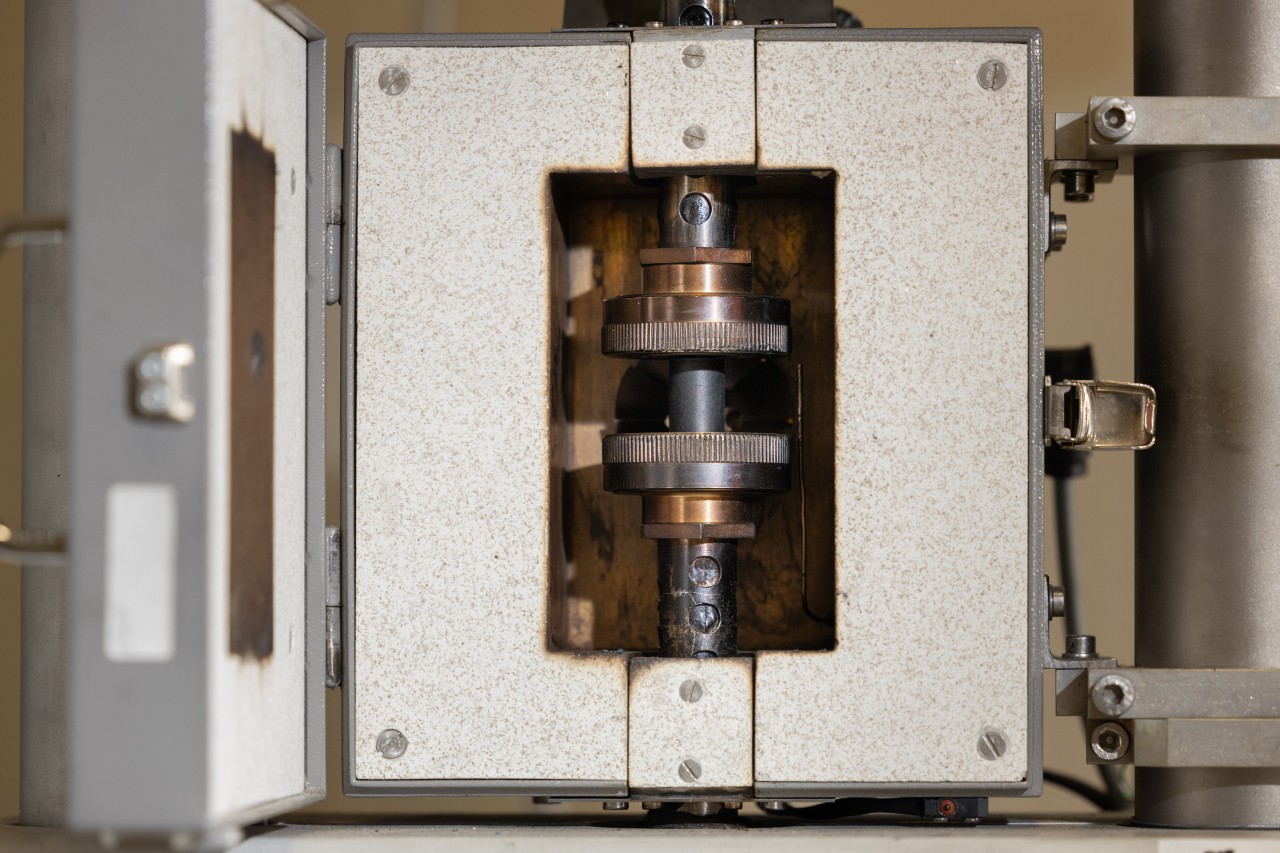

Compound mixing (also multi-stage mixing) ISO2393

There are two mixing lines. One for carbon black-filled and one for coloured or mineral-filled compounds. The mixers are 1.6-litre laboratory scale Banbury-type mixers, with variable rotor speed, so that temperature during mixing can be controlled. Both the required force and the actual temperature of the mixer are recorded. ERT uses a fixed mixing scheme for most compounds, unless otherwise specified.

Mixing is carried out according to ISO standard 2393, unless otherwise specified.

Do you have a question about mixing compounds?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Vulcanisation of test pieces and/or product prototypes ISO 2393

ERT has three electrically heated compression moulding presses with a 300x300mm plate. We have, of course, moulds available to manufacture all ISO-standardised test pieces. In addition, we can have simple one-off moulds made for small-scale prototype production.

Do you have a question about vulcanising test pieces?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Post-curing of test pieces and/or products

To finalize the vulcanization, rubber materials, in particular peroxide-cures, require post-curing after regular vulcanization in a production tool. The post-curing step extends the vulcanization degree and removes reaction products through evaporation.

Do you have a question about the post-curing of test pieces?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Information request about compound development

Privacy

Your information will not be used for any other purpose and will not be provided to third parties. Your data can be deleted at any time. For more information about how we process your data, please see our privacy statement.

We will be happy to help you

Location

Elastomer Research Testing BV

Teugseweg 27

7418 AM Deventer the Netherlands

Postal address

Elastomer Research Testing BV

PO Box 2149

7420 AC Deventer the Netherlands

Contact

E info@ertbv.com

T +31 570 62 46 16

F +31 570 62 57 02