About ERT

Elastomer Research Testing BV Is an independent, ISO17025 accredited research and testing laboratory for rubber, established in 2003 under registration number L519.

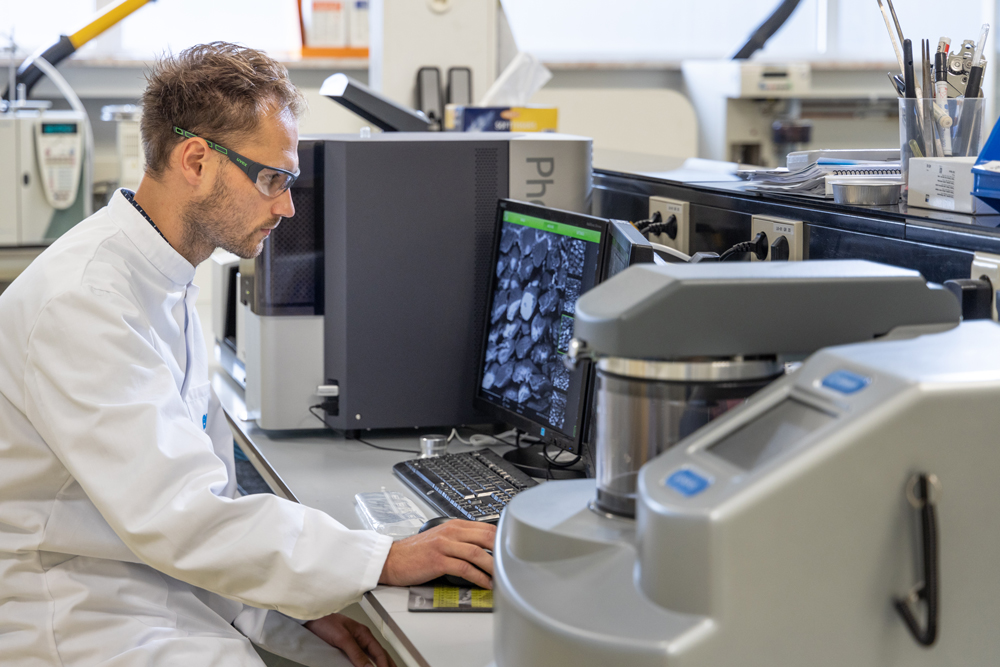

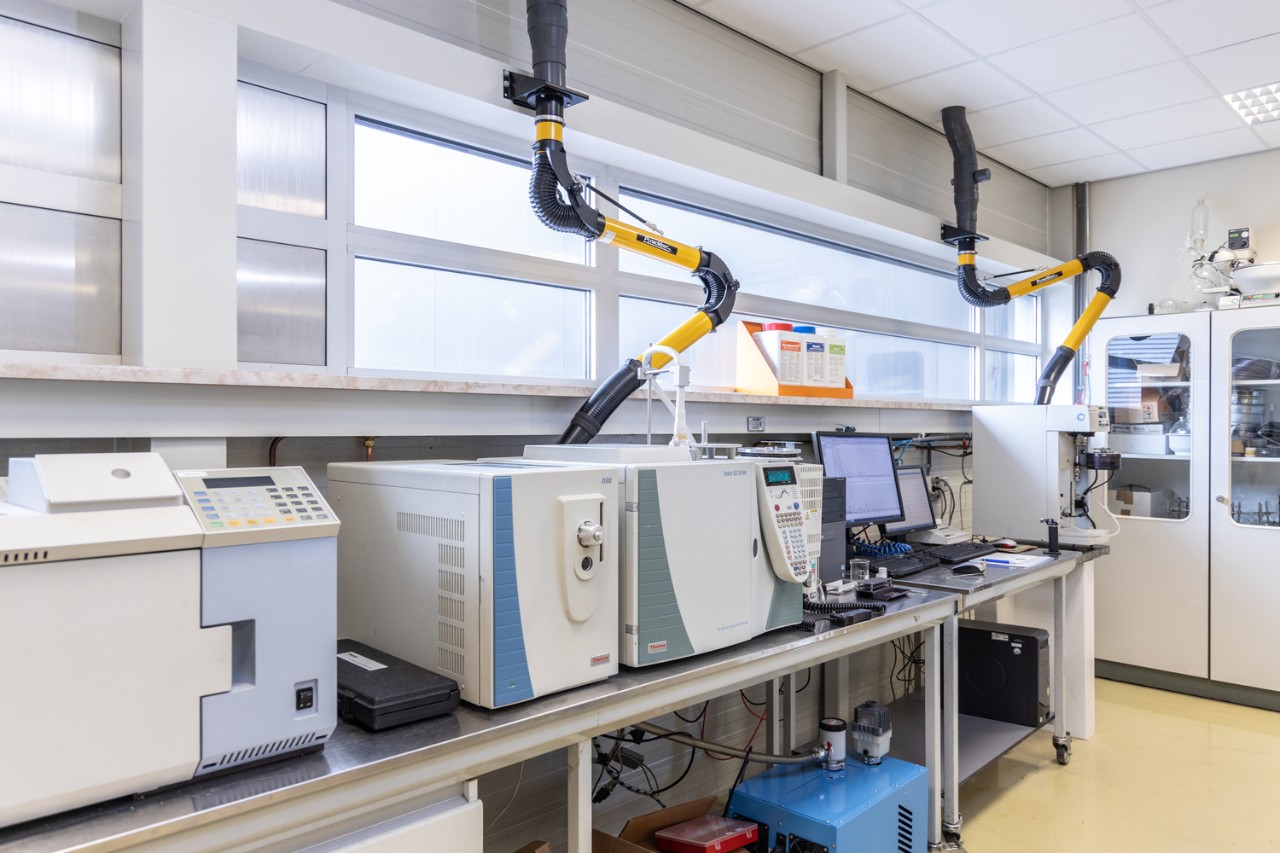

We are equipped with a wide range of the latest technology and equipment. ERT employees have in-depth academic knowledge and years of practical experience in the rubber industry. They have, of course, a thorough technical background and extensive experience in their field of expertise.

ERT customers come from all across the rubber value chain from cradle-to-cradle: from raw material suppliers, manufacturers and end-users of rubber products to commercial enterprises and recycling companies.

You can count on us for knowledge and professionalism, innovation and creativity, an extensive network and short delivery times. Confidentiality is of course guaranteed at all times. In addition, ERT is an involved party that likes to work with its customers.

Our motto is 'Innovation through partnership'.

For expertise in the field of elastomers, Elastomer Research Testing BV (ERT) in Deventer is the right place. Our employees are highly experienced and specialised in developing and testing rubbers. A unique combination of activities, interesting for all players in the rubber industry.

Accreditation statement and scope

We are proud to have been accredited to ISO/IEC17025 standard since 19 January 2011 This international standard specifies general requirements for competency in performing tests and/or calibrations, including sampling.

ERT BV ISO9001:2015 certified

On 15 February and 15 March 2016, ERT BV had its annual audit and review for upgrade to ISO9001-2015, conducted by Bureau Veritas.

This audit was successful, no non-conformities were found.

View our lab

For expertise in the field of elastomers, Elastomer Research Testing BV (ERT) in Deventer is the right place. Our employees are highly experienced and specialised in developing and testing rubbers. A unique combination of activities, interesting for all players in the rubber industry.

We will be happy to help you

Location

Elastomer Research Testing BV

Teugseweg 27

7418 AM Deventer the Netherlands

Postal address

Elastomer Research Testing BV

PO Box 2149

7420 AC Deventer the Netherlands

Contact

E info@ertbv.com

T +31 570 62 46 16

F +31 570 62 57 02