Physical mechanical properties of rubber compounds

Wide variety of advanced equipment

With a wide variety of advanced equipment in the laboratory, ERT can test or measure:

The tests are carried out as standard in accordance with ASTM, DIN and/or ISO standards. We can also meet any customer-specific test requirements.

Would you like more information about the physical-mechanical properties of rubber compounds?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Density (ISO2781)

Density is the determination of the specific gravity of the material. This can be either (un)vulcanized rubber, foam, TPE or plastic. These analyses are often needed as quality control of rubber compounds and determine the amount of specific ingredients required to produce a certain volume of material. For example, to determine how many grams of rubber compound are necessary to make a particular rubber test piece or product.

The test is carried out according to ISO standard 2781, unless otherwise desired.

Would you like more information about analysing the density of rubber compounds?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

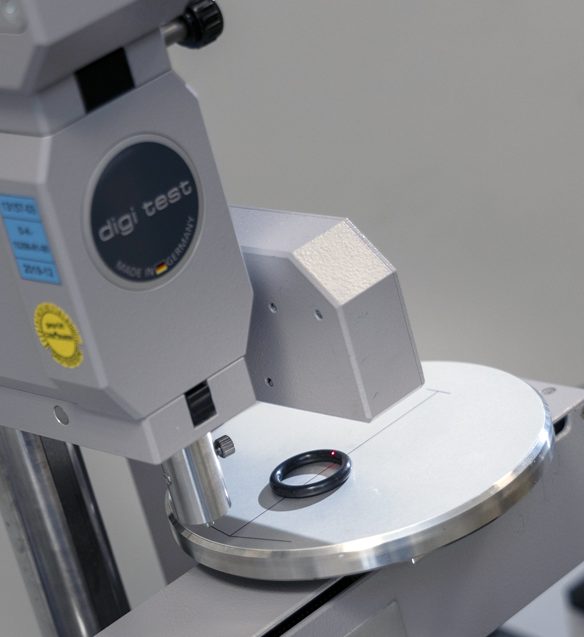

Hardness Shore A (ISO7619-1),

IRHD (ISO48), N and M

Hardness can be determined using different methods (e.g. shore A or IRHD). Shore A and IRHD N (normal) are used to measure thick test pieces, and IRHD M (micro) is used for thin test pieces or for test pieces with a particular curvature (O-rings).

The tests are carried out according to ISO standard 48 (IRHD) or ISO7619-1 (Shore A), unless otherwise desired.

Would you like more information about determining hardness?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Stress-strain properties of rubber compounds at room and elevated temperature

(tensile strength, elongation at break, stiffness (ISO-37)

Tensile strength indicates how much force or stress a rubber material can withstand before breaking. Elongation at break is the degree of strain of the material. Stiffness is expressed as, for example, modulus 100% or modulus 300%. This indicates the stress needed to strain the material 100% or 300%.

We can perform these tests both at room temperature and at application-specific elevated temperatures.

The test is carried out according to ISO standard 37, unless otherwise desired.

Would you like to know more about stress-strain properties?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Compression force diagram (bulk modulus) (ISO7743)

One of rubber's specific material properties is that it is incompressible, therefore it has a high bulk modulus, which means that it requires a significant amount of force to compress it.

The test is carried out according to ISO standard 9026, unless otherwise desired.

Do you have a question about the bulk modulus?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Tear strength (all methods) (ISO34-1)

There are various methods to measure tear strength, including crescent, angle, trouser and Delft. All these methods yield specific results, and cannot be compared. We can perform these tests both at room temperature and at application-specific elevated temperatures.

Tear strength indicates the force a rubber material can still withstand after the material is damaged.

The test is carried out according to ISO standard 34-1, unless otherwise desired.

Would you like more information about all the methods?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Resilience (Schob) of rubber compounds

(ISO4662)

Resilience is a measure of elasticity of rubber, and is important for certain applications. Rubber damping products generally require a low resilience, while elastic products require high elasticity. Rubber resilience is determined by dropping a hammer onto the rubber test sample from a predefined height and measuring how far it bounces back compared to its original height.

The test is carried out according to ISO standard 4662, unless otherwise desired.

Would you like more information about Resilience (Schob)

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Compression and tension set (also in fluids) (ISO815-1, 815-2 and ISO2285)

Rubber products (e.g. seals, gaskets) generally show permanent deformation after compression for a long time. Compression set is a standardized measure for the permanent deformation of a material after it has been compressed or strained for a predefined time under controlled conditions. The measured compression set is an essential material parameter for sealing applications. These tests can also indicate whether a material or product has been properly vulcanized.

The tests are carried out according to ISO standards 815-1 or 815-2 and ISO2285, unless otherwise desired.

Interested in compression and tension set?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

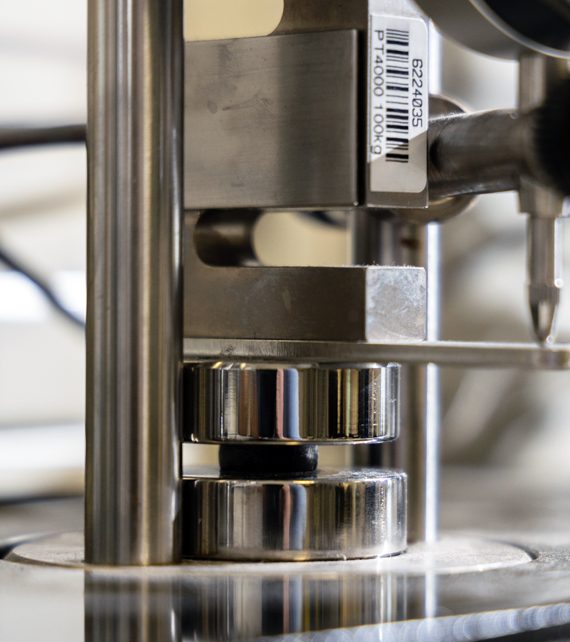

Compression and tension stress-relaxation of rubber compounds (ISO3384 or ISO6914)

Rubber is a visco-elastic material, meaning than during deformation, both in elongation and compression, a certain part of the material (the viscous part) wants to flow. This is called stress-relaxation. The level of stress-relaxation is determined by continuously recording the force required to keep a product compressed or strained at a certain rate.

Materials with a high stress-relaxation, i.e. a relatively large decrease in force over time, are more likely to leak in sealing applications.

The tests are carried out according to ISO3384 or ISO6914 standards, unless otherwise desired.

Are you interested in compression and tension stress-relaxation?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Wear resistance of rubber compounds (ISO4649)

Wear resistance is measured with a DIN abrasion test. This test involves exposing the rubber test material to a rotating drum covered with abrasive paper. After being exposed to exactly 40 metres of abrasive paper, the volume of wear in mm3 is measured.

The test is carried out according to ISO standard 4649, unless otherwise desired.

Would you like more information about wear resistance?

Please leave your details in the contact form at the bottom of this page. We will respond as soon as possible.

Information request about tests of physical mechanical properties

Privacy

Your information will not be used for any other purpose and will not be provided to third parties. Your data can be deleted at any time. For more information about how we process your data, please see our privacy statement.

We will be happy to help you

Location

Elastomer Research Testing BV

Teugseweg 27

7418 AM Deventer the Netherlands

Postal address

Elastomer Research Testing BV

PO Box 2149

7420 AC Deventer the Netherlands

Contact

E info@ertbv.com

T +31 570 62 46 16

F +31 570 62 57 02